| Alloy | Chemical composition% | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Ai | ||

| Single | Toi | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 5052 | 0.25 | 0.4 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.1 | 0.2 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-.12 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.18-0.28 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

4mil. EPE Foam interleave each piece, Bunch of pieces to be wrap with Polyolefin Shrink Film into tight bundle(less than 30kgs). Plywood bars frame the bundles into strong heavy bundle(less than 1200kgs). All framed heavy bundles to be place on wheeled steel pallet for forklift load.

4mil. EPE Foam interleave each piece, Bunch of pieces to be set into heavy duty carton(less than 20kgs). All heavy duty cartons to be place on strong plywood pallet(less than 1000 kgs) for forklift load.

How can I get the best price for Aluminum Profiles?

Understanding how we price can help you save needless expenditures. See the question below about “What is the price for an aluminum profile” for more information. Also see our Aluminium Extrusion Education Center for more information.

What is the price of an Aluminum Profile?

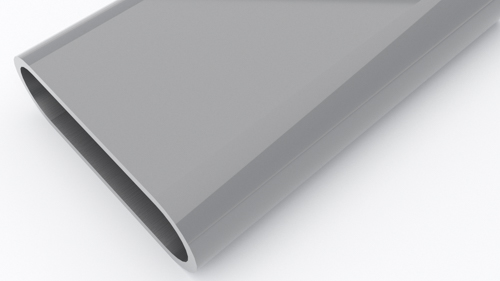

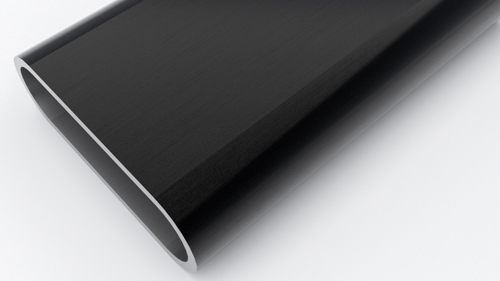

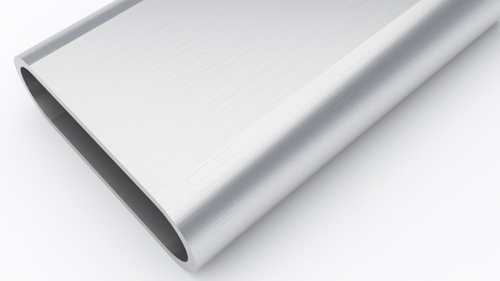

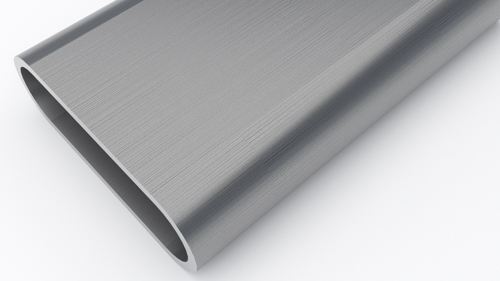

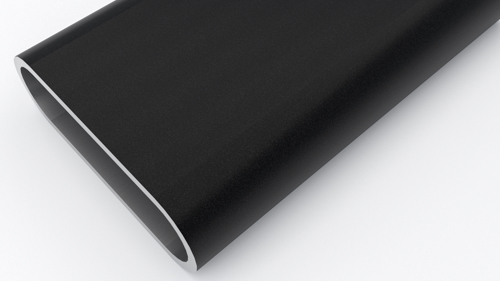

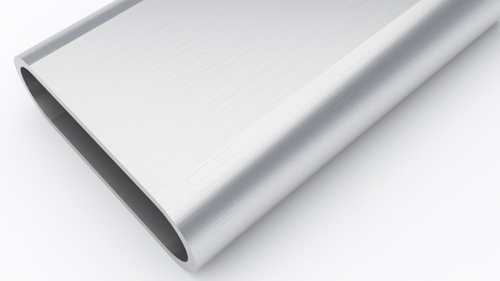

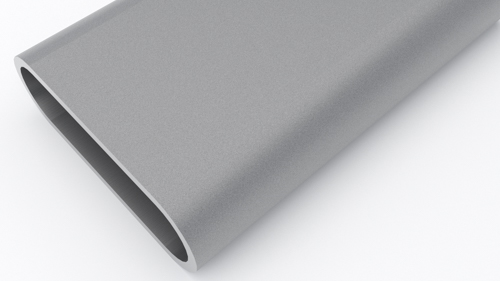

Market price of Aluminum Raw Material (Aluminum Ingot). Costs associated with smelting billet (alloy mixture) for making aluminum rods for extrusion. Costs associated with extruding, cutting aluminum profile. Additional onsite services such as (powder coating, anodizing, CNC machining, etc). Packaging Services Additional Services (R & D, Quality Control, Company staff) We offer the best competitive price and a breakdown of costs on every invoice

How soon can you produce and deliver my Aluminum Profiles?

Maximum lead time: 28 days

Minimum lead time: 7 days

Average lead time: 13-17 days

We are normally ready to build your order within a few days of machining the aluminum extrusion mould/mold. Machining a mould can take up to 7 days. Contact us to inform us of your needs so that we can provide the delivery options that are best suited for your needs.

After machining a mould. An order can take up to 10 days depending on orders in queue and the quantity you need. Once your order has been extruded, Other processes are fairly quickly, Sometimes adding on 1-3 days to lead time.

Why should we order from your factory?

Design Privacy: All of products which you provide us are never sold or given to other companies for use.

Clear and Open Communication: Communication with us is precise. Our sales and customer service team is managed and trained by native English speakers. Training includes understanding foreign customs in order to ensure a seamless, painless ordering process.

Lean Operations: Our factory sold over 30,000 metric tons of quality aluminum profiles and products last year.

Business Experience: We have been in business for over 21 years. 21 years of constant growth and stability as we meet the demands of our customers with perfection. We understand quality enough to be where we are at. We always strive to separate ourselves beyond meritocracy when it comes to you.

Arch Aluminum Brand: Our brand represents the excellence of aluminum extrusions. Our certifications and quality control team meet or exceed industry standards.

What file format should I send for my Aluminum Profiles design?

File formats vary. PDF’s, JPEG, STEP, STP, IGS and CAD, are all very popular file formats. Send us the design file format that suits your best.